BRIGHT ALLOY Shipments Low aluminum and Low Carbon Ferrosilicon for Australian Customer.

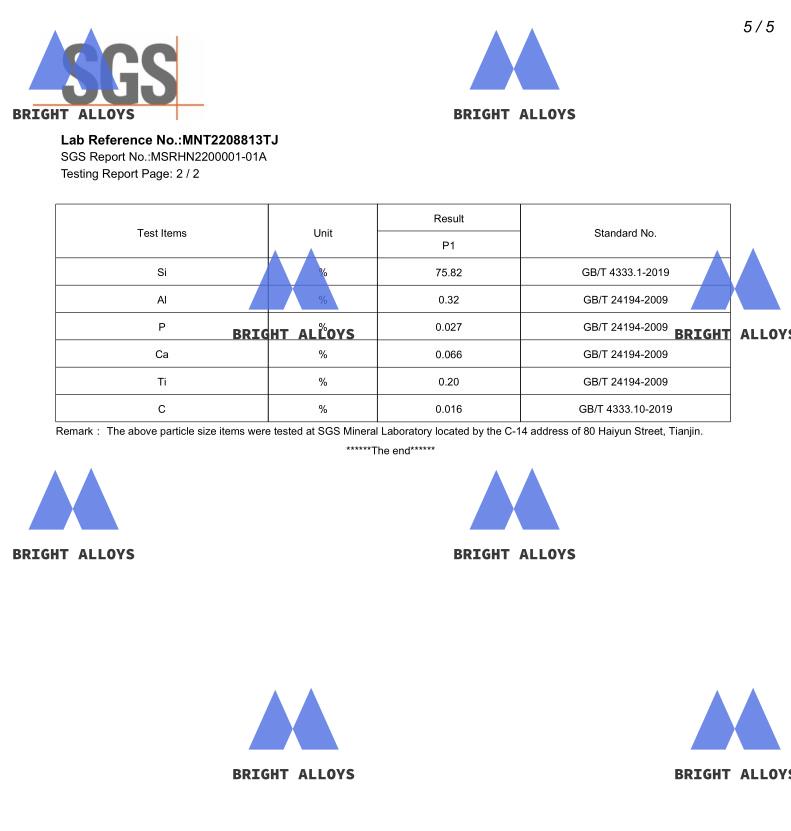

For this batch of goods, the customer requires very low aluminum content, and the ordinary ferrosilicon and aluminum content is between 1.3-2.0%.Due to the special production process of the customer’s steel,the requirements for raw material standards are relatively high, and the aluminum content is required to be below 0.4%.And BRIGHT ALLOY has its rich experiences for handling the request.

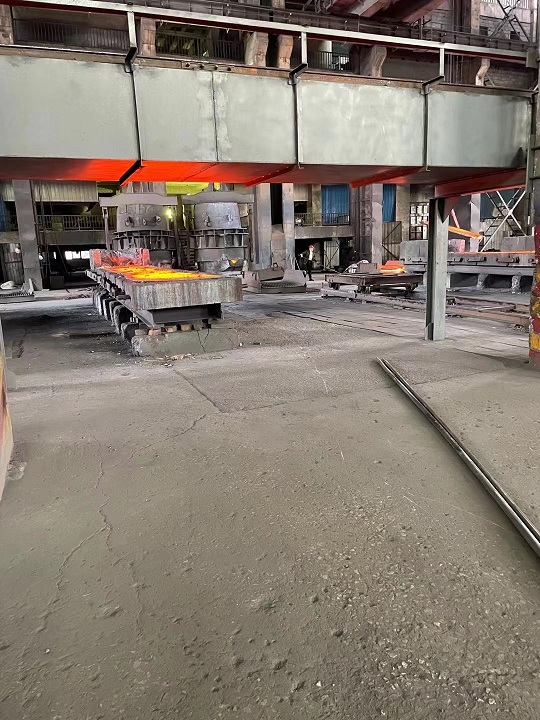

Our factory selects raw materials with low aluminum and carbon content for production.During the production process, the refining process is carried out many times to remove excess aluminum and carbon elements to meet customer expectations.

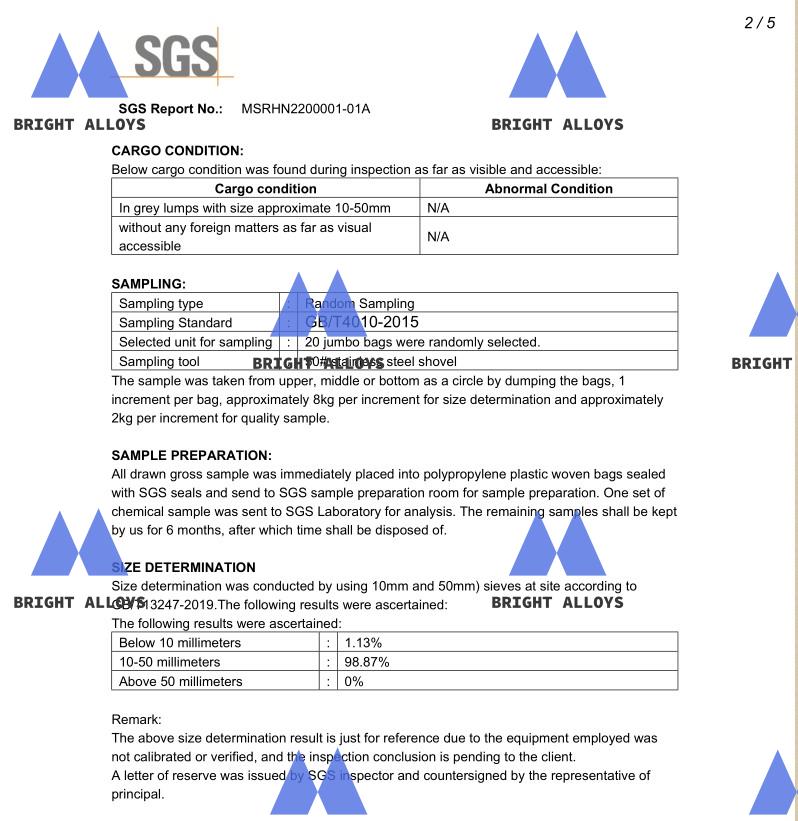

The size requirement is 10-50mm, and BRIGHT ALLOYS conducts two passes of automatic screening to obtain a higher standard particle size qualification rate.

SGS inspection results, the report fully meet the customer’s expected requirements, the pass rate of particle size 10-50mm exceeds 98%

The container is packed and reinforced with wooden support to prevent the container from being dumped out of the container when it is unpacked at the destination port.

BRIGHT ALLOYS has been specializing in the production of various types of ferrosilicon for nearly 20 years,and has formed an advantageous industrial supply chain in terms of price and quality assurance in the production and processing industries of low-carbon, low-aluminum ferrosilicon, ordinary ferrosilicon, and high-carbon ferrosilicon.

It has supplied various types of ferrosilicon raw materials to many large steel mills in China, as well as foreign large steel mills and foundries to meet the needs of various types of steel production.For more information or price about ferrosilicon,you are welcomed to contact us at info@brightalloys.com.