How to choose a heating agent for high steel-scrap ratio in steel treating?

Due to fluctuations in the supply of iron ore,cost reasons.Increasing the proportion of steel scrap added,improving processes and reducing costs have become the popular choice of many steel mills.

But after increasing the scrap ratio,there will be insufficient heat in treating,due to the low temperature of molten iron,the long transportation time of molten steel,the large temperature drop,a temperature-enhancing agent needs to be added to ensure heat balance. it is necessary to regulate the use of heating agent to reduce the impact on the smelting operation.

At present,the ones that can be added to the converter include calcium carbide,silicon carbide,ferrosilicon,coke, etc.

Calcium carbide has a high cost and a slow melting speed in the converter,and there is unreacted calcium carbide in the final slag of the converter,which makes the heating efficiency unstable.

Silicon carbide as a temperature raising agent has high cost and reacts to generate silicon dioxide, which increases the consumption of slag,and the addition amount is not easy to be too large,and the use is limited.

As a heating agent,ferrosilicon is easy to control in size and stability, and the furnace loading operation is also more streamlined, the flexibility of use is high, and the dosage is controllable,but cost is too high.

As a heating agent, coke is widely used in various types of converters because of its low cost, fast melting speed and high heating efficiency.However,the sulfur content may be high, which limits its use.

Mainstream steel mills choose to use a combination of coke and silicon carbon to ensure the heating effect.

If to reduce cost,the use of high carbon ferrosilicon/silicon-carbon alloy briquette is a good solution.

| Si | C | Al | P | S | |

| Si-C alloy briquette | 50-55% | 15-20% | 0.5-2% | 0.05%max | 0.05%max |

| Si-C alloy briquette | 60-65% | 20-25% | 0.5-2% | 0.05%max | 0.05%max |

| HC ferrosilicon | 65-70% | 15-22% | 0.5-2% | 0.05%max | 0.05%max |

| HC ferrosilicon | 68-75% | 18-25% | 0.5-2% | 0.05%max | 0.05%max |

High carbon ferrosilicon/silicon carbon alloy briquette have high silicon content,high carbon content,low impurity content,good heating effect and low cost.

The cost of silicon carbon alloy briquette is only a few hundred dollars per ton,and high carbon ferrosilicon around 1,000 dollors/ton,they can perfectly the coke and ferrosilicon combination process,reduce the cost and increase the heating effect.

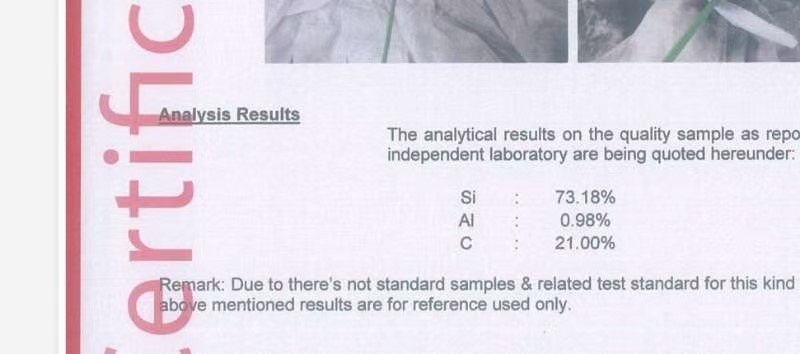

Brightalloys is a producer for high carbon ferrosilicon and silicon-carbon alloy briquette,for more information about high carbon ferrosilicon and silicon carbon alloy briquette,please contact us @ info@brightalloys.com

Free sample available.