How Silicon Briquette repalce ferrosilicon and reduce cost in steel-making industry?

Silicon briquette can be widely used as deoxidizer in steelmaking industry instead of ferrosilicon. Speciality is to adding silicon element in the process of deoxidation to deoxidize oxygen in molten steel and reduce ferrosilicon added.

| Product Price | $700.00 |

Product Description

Silicon briquette(silicon ball) is made of silicon raw materials,different product specifications can contain 50%, 60% and 70% silicon.

In the smelting process,silicon has affinity with oxygen,and the high silicon content and high recovery rate of silicon briquette can enable the deoxidation ability replace that of ferrosilicon,for instance,use 6KG 65% silicon briquette replace 5KG 70% ferro silicon,the deoxidation effect same in level.However,the cost is far lower than that of ferrosilicon,so as to reduce the ferrosilicon cost.

High silicon content makes it can can achieve unexpected good treating effect,therefore,the main application of steel manufacturers to use it to replace partial or full ferrosilicon materials is to save costs and increase profits.

Chemical of silicon ball

| 60% Silicon | Si 60% min | C 3% max | Al 5%max | S 0.05% | P 0.05%max |

| 65% Silicon | Si 65% min | C 3% max | Al 5%max | S 0.05% | P 0.05%max |

| 70% Silicon | Si 70% min | C 3% max | Al 5%max | S 0.05% | P 0.05%max |

In addition to the silicon content,the remaining small amount of elements calcium,aluminum and carbon can adjust the slag removal of molten steel according to the needs of different steel types,which is very easy and will only have a small amount of slag removal cost.In general, the cost can be saved by 30-50%.

Usage of silicon briquette:

In the process of alloying,the weight of silicon ball to be added can be calculated according to the weight of ferrosilicon silicon element.Generally,the added weight is slightly more than the weight of ferrosilicon to be added to the furnace. The recovery of can reach 90%.

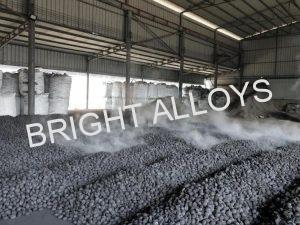

Size of silicon briquette:

50*30*30mm (egg size)

Packing:

1mt/1.25mt PP bag

Sample testing is welcomed!Free sample available,please contact us for details:info@brightalloys.com

Leave us Message:

Silicon Carbide Alloy Briquette(Silicon 55%,C 15%,replace ferro silicon and recarburizer)