Silicon Manganese

Silicon-manganese alloy is an indispensable composite deoxidizer and alloying additive in steelmaking. Composed of silicon, manganese, iron, and trace amounts of other elements, it is widely used in the production of a variety of steel products, including plain carbon steel, stainless steel, and alloy steel, due to its high efficiency and cost- effectiveness. Whether it’s the sturdy steel bars of magnificent skyscrapers and cross-sea bridges, or the core components of automobiles and mechanical equipment, the remarkable performance of silicon-manganese alloy is behind them. It can be said that silicon-manganese alloy is the “vitamin” of the modern steel industry, playing a vital role in improving steel quality.

Product Description

1. Main product specifications (GB/T 3795-2014)

We strictly follow the national standard (GB/T) and produce a variety of specifications of silicon manganese alloy to meet the different needs of customers. The following are the detailed parameters of two mainstream specifications:

| Brand | Chemical composition (mass fraction) % | Processing size | ||||

| Mn | Si | C | P | S | ||

| FeMn65Si17 | ≥ 65.0 | 17.0 – 20.0 | ≤ 1.8 | ≤ 0.10 | ≤ 0.04 | 3-10mm , 10-60mm or customized as required |

| FeMn60Si14 | ≥ 60.0 | 14.0 – 17.0 | ≤ 2.0 | ≤ 0.30 | ≤ 0.04 | 3-10mm , 10-60mm or customized as required |

Particle Size: We offer two standard particle sizes. Smaller sizes ( 3-10mm ) are suitable for refining in converters and electric furnaces, offering fast melting speeds and high reaction efficiency. Medium- to large-size sizes ( 10-60mm ) are more suitable for smelting in submerged arc furnaces and large electric furnaces, effectively reducing burnout and dust while increasing yield. Customized particle sizes are available to meet your specific process needs.

2. The key role of silicon and manganese in steel

As alloying elements, silicon and manganese play complementary roles in steel, together giving steel better properties:

The role of manganese (Mn):

- Deoxidation and desulfurization: effectively remove oxygen and sulfur from molten steel, reduce harmful impurities, and significantly improve the hot working properties (such as hot rolling and forging) and toughness of steel .

- Solid solution strengthening: dissolves in ferrite to enhance the strength and hardness of steel .

- Improve hardenability: Increase the hardening depth of steel during heat treatment to make the performance of large cross-section components more uniform.

The role of silicon (Si):

- Enhanced deoxidation: It is a stronger deoxidizer than manganese, which can further purify the molten steel, form non-metallic inclusions that are easy to float, and improve the purity of the steel .

- Significant strengthening: Silicon has a very significant solid solution strengthening effect on ferrite, which can greatly increase the strength and elastic limit of steel while maintaining good plasticity.

- Improve corrosion resistance: Improve the oxidation resistance of steel.

- Synergistic effect: Silicon and manganese work together to produce steel with excellent strength, toughness and ductility. The combined effect is far superior to adding ferrosilicon or ferromanganese alone, making it an ideal choice for optimizing production processes and reducing costs.

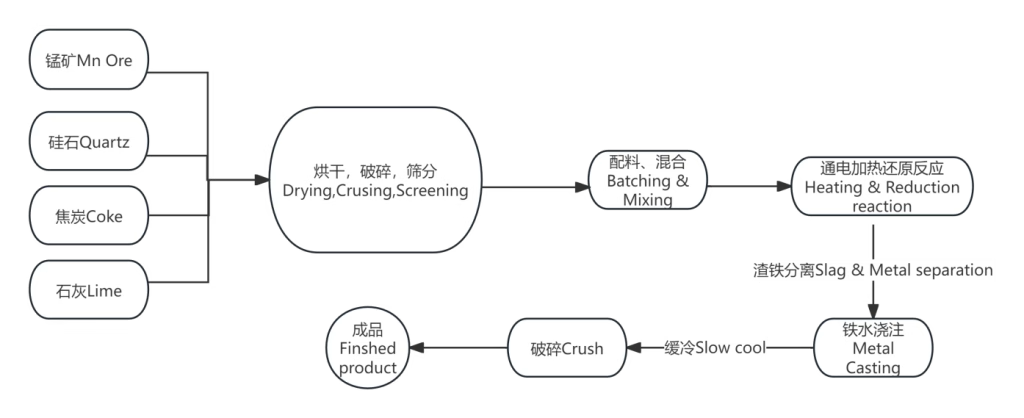

3. Production methods

Advanced production technology:

We utilize a sophisticated submerged arc furnace smelting process . We carefully select high-quality manganese ore, silica, coke, and other raw materials, precisely proportioning them using a computer-controlled batching system. The reduction reaction proceeds in a high-temperature electric arc furnace to produce high-quality silicon-manganese alloy hot metal. Through multiple processes including casting, cooling, crushing, and screening, we ultimately achieve a finished product with stable composition and uniform particle size.

4. Quality assurance

Quality is the lifeline of an enterprise. We have established a full-process quality monitoring system:

- Raw material inspection: Strictly inspect incoming raw materials to ensure quality at the source.

- Process control: Real-time monitoring of key parameters such as furnace temperature and current during the smelting process to ensure process stability.

- Finished product inspection: Samples are taken from each batch of products and chemical composition analysis is performed quickly and accurately using advanced equipment such as direct reading spectrometers to ensure that all indicators meet national standards and customer requirements.

- Physical inspection: Strictly screen and inspect the particle size and appearance of the product to ensure that the physical condition of the product is excellent.

- Traceability: Each batch of products has an independent identification, which enables full quality traceability from raw materials to finished products.

Choosing us means choosing stable and reliable quality and a trustworthy partner. Welcome to contact us for inquiries and negotiations!

Product Features

| Size | 10-60 mm |

| Weight/Packing | 1 metric ton |

| Delivery Time | 7 days |

| Product Origin | CHINA |

| Third Party Quality Inspection | YES |